Kreiselbrecher

- Home

- Kreiselbrecher

Gyratory Crushers BS Series

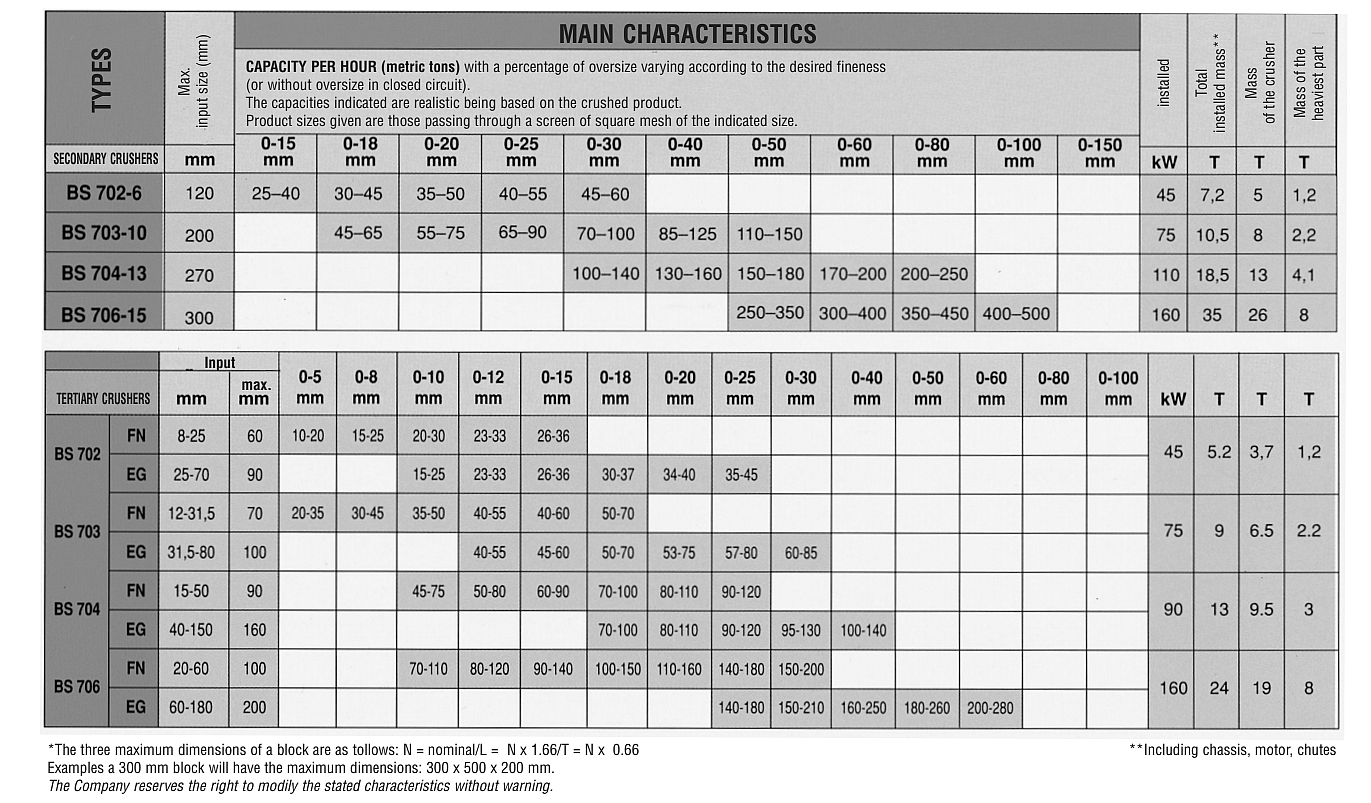

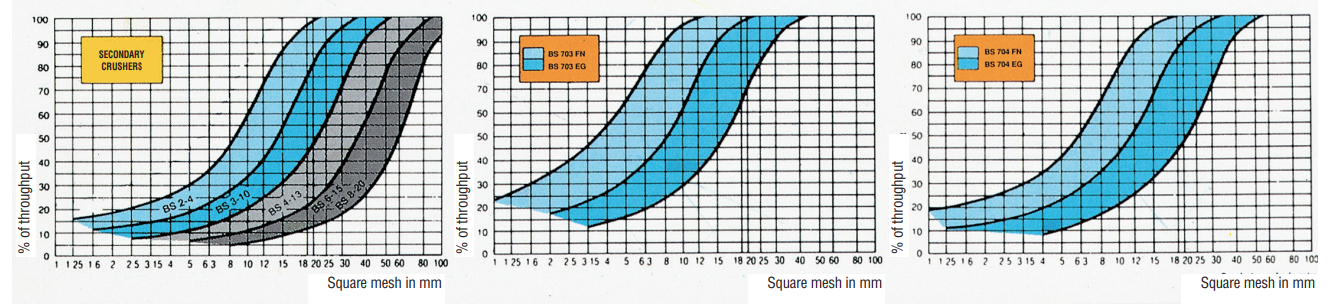

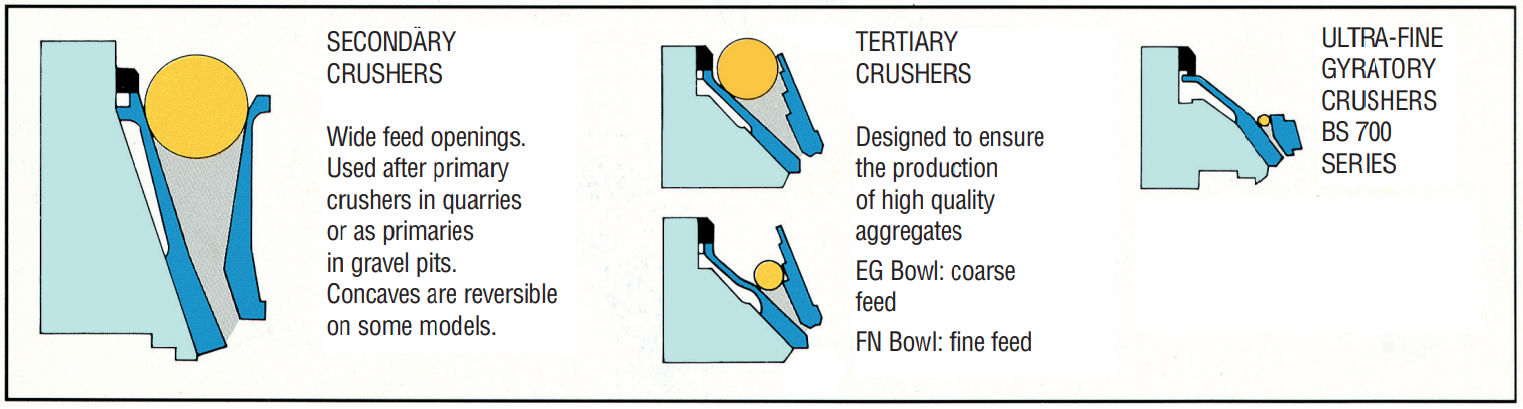

CHARACTERISTICS AND APPLICATIONS OF SECONDARY CRUSHERS

These are used either as “primaries” in gravel plants, or “secondaries” in quarries, following high capacity jaw or gyratory primary crushers.

The only difference between this and other types is the large

feed opening of their crushing chamber, which for some sizes is equipped with reversible concaves.

All the parts of the crusher, the crushing chamber excepted, are

interchangeable and standard.

CHARACTERISTICS AND APPLICATIONS OF TERTIARY CRUSHERS

These are „granulators“ par excellence, designed to give remarkably cubical crushed products.

They only differ from other types in their crushing chambers. On these versions two types of chamber are available: FN or EG. These bowls have a special profile to ensure consistency of discharge and best use of the wearing parts.

It is to be noted that FN and EG vowls are easily interchangeable.

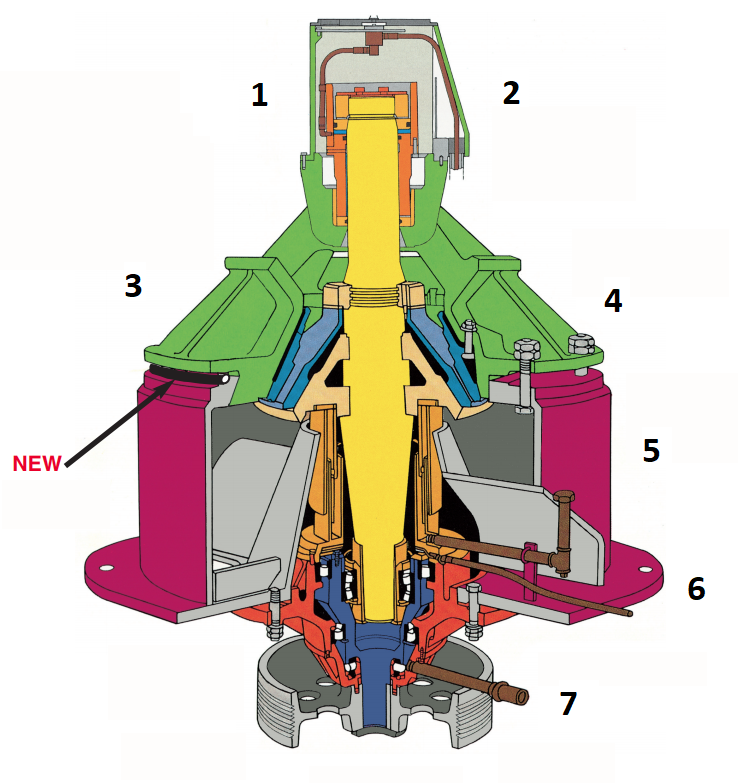

Cross-sectional view

The initial level of protection agains overloads is achieved by an oleopneumatic accumulator. This operates without stopping the crusher which automatically returns to its original setting once the overload has been cleared. The second level of protection consists of a high pressure switch which dumps the shaft, stops the crusher motor and operates alarms.

Hydraulic shaft suspension for remote adjustment of the setting and compensation for wear.

New: hydraulic fastening system without screw bolts.

Patented double labyrinth sealing system to protect the mechanism.

Easy conversion from EG to FN by exchange of crushing chambers.

Oil lubrication by motorised pump and pressure filter.

Direct vee-belt drive. No counter-shaft.

- High speed short stroke action.

- Flywheel directly keyed to the eccantric.

- Mechanism fully fitted with large roller bearings for maximum mechanical efficiency.

Technical data

Dimensions

| BS 702-6 |

BS 703-10 |

BS 704-13 |

BS 706-15 |

BS 702 |

BS 703 |

BS 704 |

BS 706 |

|

|---|---|---|---|---|---|---|---|---|

| A | 3350 | 3600 | 4200 | 5000 | 3350 | 3600 | 4200 | 5000 |

| B | 1450 | 1950 | 2350 | 2800 | 1450 | 1950 | 2350 | 2800 |

| C | 2155 | 2625 | 2925 | 3800 | 1915 | 2260 | 2445 | 3270 |

| D | 1970 | 2000 | 2000 | 3000 | 1420 | 1700 | 1988 | 2480 |

| E | 215 | 350 | 520 | 550 | 215 | 350 | 520 | 550 |

| F | 390 | 600 | 740 | 800 | 390 | 600 | 740 | 800 |

| G | 3200 | 3600 | 4000 | 5150 | 3200 | 3500 | 3800 | 5150 |

| H | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 |